Engineered Human-Touch

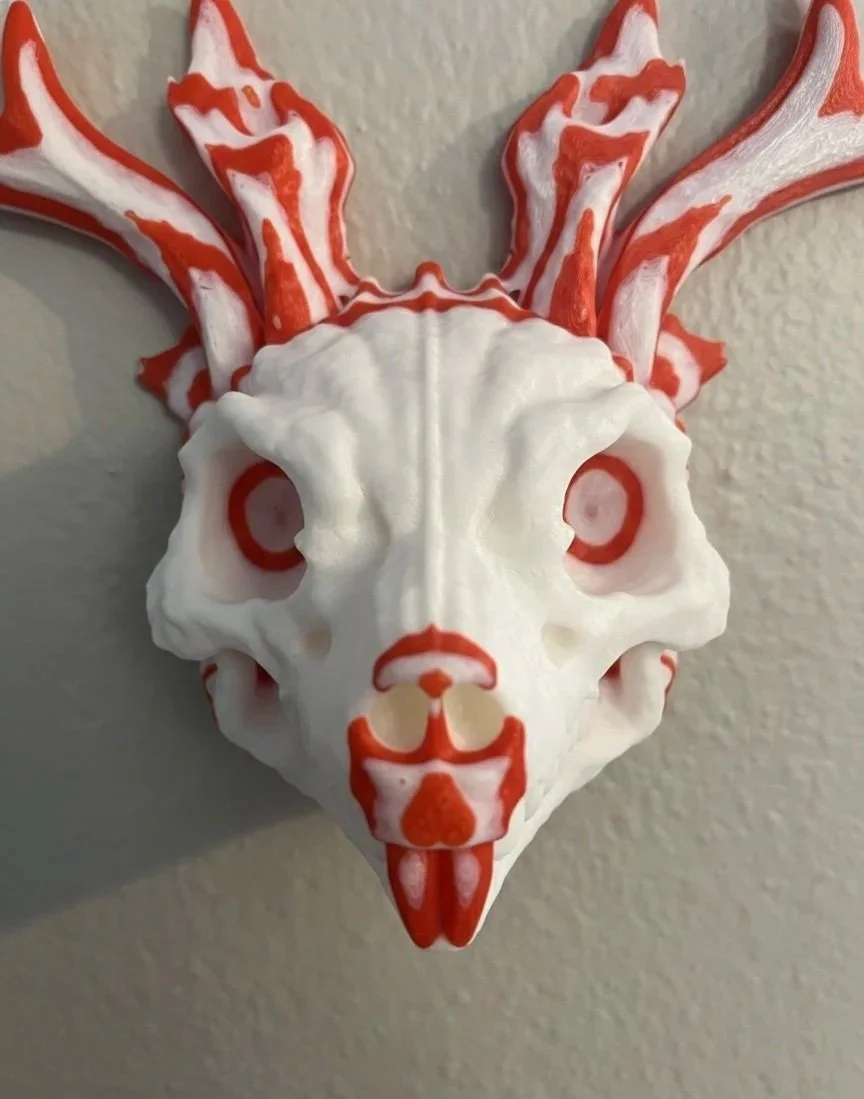

At the I-5 Recovery Hub, we don’t believe in "set it and forget it." Every Marrow-Bound Jackalope is the result of a grueling, hands-on manufacturing cycle designed to push the limits of desktop fabrication.

The Zero-Waste Purge Protocol: Unlike mass-market printers that use wasteful automated systems (AMS), each color transition in our specimens is managed through a custom-engineered manual purge method. This allows for sharper color transitions and superior structural integrity while minimizing environmental plastic waste.

The Vigilance Cycle: To ensure "Specimen" quality, our lead technician monitors the print throughout the entire 24+ hour cycle. This includes manual intervention every two hours to manage filament dynamics and ensure the "bone-grain" texture remains flawless.

Vibration-Stabilized Foundations: Every unit is birthed on a specialized Porcelain-Anchor System. By mounting our heavy-industrial printers on high-density porcelain and acoustic foam, we eliminate "ringing" and "ghosting" artifacts, delivering a surface finish that feels more like carved stone than printed polymer.

Slicer-Optimized Geometry: We don't use standard profiles. We "fight the slicer" so you don't have to—manually pathing every layer to ensure the antlers have the strength of a trophy mount and the skull has the intricate detail of a museum piece.

The Curated Audit: To ensure maximum network security and customer privacy, we provide individual progress reports rather than public streams. Every specimen is documented with photos and video throughout its 24+ hour lifecycle. This allows us to verify layer consistency at 120mm/s without ever compromising the Hub’s secure local network.

The Full-Cycle Archive: Upon request, we provide a complete frame-by-frame timelapse archive. Witness every manual filament swap and the precision of the "No-AMS" purge method from start to finish.